ALVATEX

TECHNICAL STANDARDS

Fiberglass mesh

Essential for the quality of the final product is carefully choosing the raw materials.

01TECHNOLOGY

The mesh quality results not only from the carefully selected raw materials, but also from the precision of the technological process.

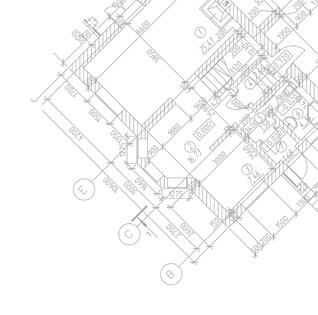

02FABRICĂ

The design of the manufacturing floor optimizes internal logistics flows, shortens work times and increases production capacity.

03PRODUSE

We produce fiberglass mesh for ETICS, internal use, universal use and screed reinforcement.

WE ARE AT YOUR SERVICE

Tell us about your project and find out how we can help you!

ANSWERS

NEED ANSWERS?

Frequently asked questions

We're trying to answer as simple as possible to the most frequently asked questions about fiberglass reinforcement mesh.

- Quality of the glass fibers from which it is woven, both of the warp yarn and roving

- The quality and quantity of the adhesive in percentage ratio to the nominal weight of the net

- The method or technique of weaving glass fibers.

- High-performance equipment that processes the wires at all stages of the production flow accurately and without defects.

- In other words, as you can see, almost everything matters!

TESTIMONIALS

What our partners say about Alphaterm

I recently renovated my summer house and, after a little research, I chose fiberglass meshes made by Alphaterm. The workers from the company that took care of the renovation told me I made a good choice, and I found some of the best meshes available on the market.

As an owner of a construction firm, I’m always searching for better materials and solutions that I can use and recommend to my clients. So, after passing through almost all the products available on the market, I can say that the alvatex line makes the top 3 of value for money products.

NEWS & ARTICLES

STAY IN THE LOOP

Blog

Anunț angajare Alphaterm – Operator țesere – Chișinău

Te invităm să faci parte din Echipă! Cu noi, poți să treci gratuit cursurile de...